Double Stick Installation

Underlay is adhered to the sub-floor using a release type adhesive. Carpet is fully adhered to the underlay using a permanent type adhesive.

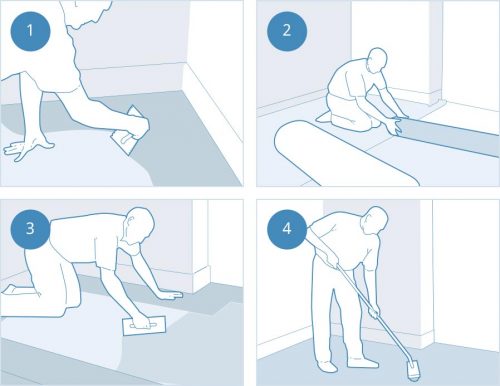

- Apply tackifier to sub-floor using a roller, tackifier trowel or brush and allow to dry.

- Lay out the underlay onto the sub-floor (printed side up) ensuring the underlay seams are closely butted together and run at 90° to any carpet seams.

- Apply carpet adhesive to the backing using a Durafit, or B2, notched trowel.

- Lay the carpet into the wet adhesive and smooth out any fullness or air bubbles with a Glider.

Advantages

- Helps reduce the risk of rucking in high traffic areas

- Avoids the need for sewn or heatbond seams

- Gripper fixings and stretching not necessary

- Enables perfectly straight borders

- Quiet and fast installation in large areas

- Improved flame retardancy of final floor build-up

Disadvantages

- Installation cost is higher but maintenance costs are lower